Warehouse product management has never been more effective. Invident is an IT system of the WMS class that meets the expectations of the most demanding managing directors: it effectively automates and optimizes the processes of Warehouse Management, allows you to control the planning of production and logistics events in online mode, allows you to create advanced work performance reports throughout the entire supply chain.

Processes in WMS Invident are supported by automatic identification (AI), therefore working with a mobile terminal allows you to quickly collect and process all product data in the system.

The software was built from two basic modules: warehouse and production and two innovative extensions: READY TO RFID and READY TO VOICE.

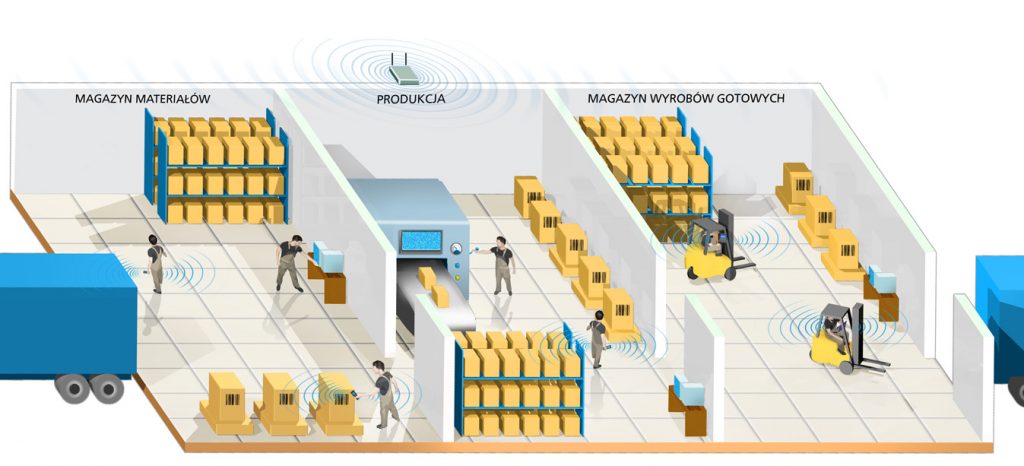

WMS or Warehouse Management System is the software most often used in logistics to optimise warehouse and production processes. It allows you to administer the movement of products from the receipt of raw material at the warehouse to the release of the finished product to the customer. All product data is collected using barcodes. Modern devices are used for this purpose: scanners, readers and data collectors.

The modern WMS solution has been designed in a way as to organise all matters related to the identification of products in stock and, more importantly, to improve the functionality and work efficiency of an enterprise. The WMS Invident system objectives are:

In logistics companies, WMS software often supports the ERP (Enterprise Resource Planning) systems. This cooperation is possible due to data exchange between these softwares. The benefits of such a solution are primarily:

Accurate tracking and full supply chain management allow you to control and effectively plan the logistics and production processes. The WMS Invident system provides information on whether what is needed is produced, in what quantities, how it is delivered to customers, and what is the order status on the suppliers end. All adverse events that reduce efficiency are quickly identified and eliminated. A single system enables management of production, warehouse, quality control, shipping and order making to the suppliers in real-time. A single supplier can therefore efficiently manage, maintain and service the entire system while optimising all its processes:

Advanced WMS algorithms optimising the operation of the Invident system in the areas of storage and transport of materials and finished products are the core of the system. Warehouse processes can be carried out in various ways such as mobile, real-time or with simultaneous or complete elimination of documents in paper form.

The extensive functionality allows for effective handling of the following warehouse processes:

PZ – external acceptance can be implemented by the warehouse system according to set scenarios in connection with the strict supplier system for orders. During the PZ process, advanced control procedures (quantity control, expiry date monitoring, batch number registration and others) are carried out.

WZ – external edition, which is efficient and error-free. Thanks to the implemented warehouse management process (WMS) mechanisms, various WZ implementation methods are possible; cross-docking, packaging, individual labelling, etc. It is possible to label shipping units with individual logistic labels in accordance with the GS1 standards.

RW, PW, MM – ensure the movement of goods and materials within one enterprise. Different levels of restrictiveness and individual access rights to perform individual functions are possible.

Inventory – carried out according to many parameters, e.g. supplier, batch, locations, goods, etc. The user has the following types of inventory at his disposal: continuous, random, handover and settlement.

WMS Invident provides support for production plants with various production organisation methods, such as stream; discrete; process; sequential; and custom productions. In addition, the system implements full production traceability, material control, production reporting, semi-finished product labelling, unit products, collective packaging, pallets, etc. Each production order has an appropriate status while the settlement of changes takes place in a fully automated manner.

The production module allows for:

(PL)

System WMS Invident rozwija się wraz z rozwojem e-commerce i odpowiada również na wymagania usługodawców logistycznych. System w swojej standardowej wersji umożliwia uruchomienie procesów pod usługę fulfillment dzięki: elastyczności konfiguracji pod wielu właścicieli, wbudowanym mechanizmom wspomagania procesów kompletacji i zatowarowania regałów, prognozowaniu promocji i sezonowości towarów kontrahentów, co pozwala na zwiększenie ich dostępności na magazynie. Umożliwia także dostęp do ręcznego zarządzania zadaniami.

W swojej ofercie mamy również możliwość integracji z firmami kurierskimi, systemami CMS i platformami E-commerce dzięki uniwersalnemu API. Co więcej – dzięki możliwości zastosowania infrastruktury chmurowej możemy zwiększyć skalowalność infrastruktury, co umożliwi obsługę dużych transakcji bez opóźnień.

Moduł fulfillment umożliwia między innymi:

Invident ready to RFID’ is an extension of the Invident production and the warehouse management system. Thanks to this module, support for the warehouse as well as the production and logistics processes has become easier. This is because, in addition to standard labels containing barcodes which are commonly used today, our WMS system also provides support for the RFID tags. The elements that make up the extension are RFID tags, RFID readers and software.

Discover the benefits of using RFID technology.

The use of RFID gates can easily automate some of the processes that are carried out manually by the users. For example, if the RFID tags will be assigned to cars, the Invident system will be able to record when they pass through a gate using RFID readers. This, in turn, can record the exact arrival or departure of such a car.

Invident ready to RFID’ system provides support for two work models; the stationary one with RFID gates and a mobile one with RFID terminals. Work can also be done within distributed architecture. This work model is used to manage transport or pallet circulation. As the data from RFID identifiers is transmitted to readers by radio, it is often exposed to various types of attacks. This is why software is protected with the help of latest data encryption techniques and user authentication. Mobile terminals ensure data security both in case of communication with the server via WiFi and GSM.

Invident ready to VOICE’ is an additional module for the Invident production and warehouse management system that allows interaction with the system user based on voice commands.

This support extension allows for faster execution of production and logistics processes. This is because the system prompts the user to follow subsequent commands through a headset. Their execution is then verbally confirmed through a microphone connected to the terminal. The time yield resulting from this approach is particularly visible during the implementation of order picking and delivery processes.

Order picking – faster, more efficient and effective – learn more!

Trusted, reliable offer – we have the best WMS offer for companies that are looking for a ready and comprehensive solution. Start working with us today.

The WMS solutions package includes: